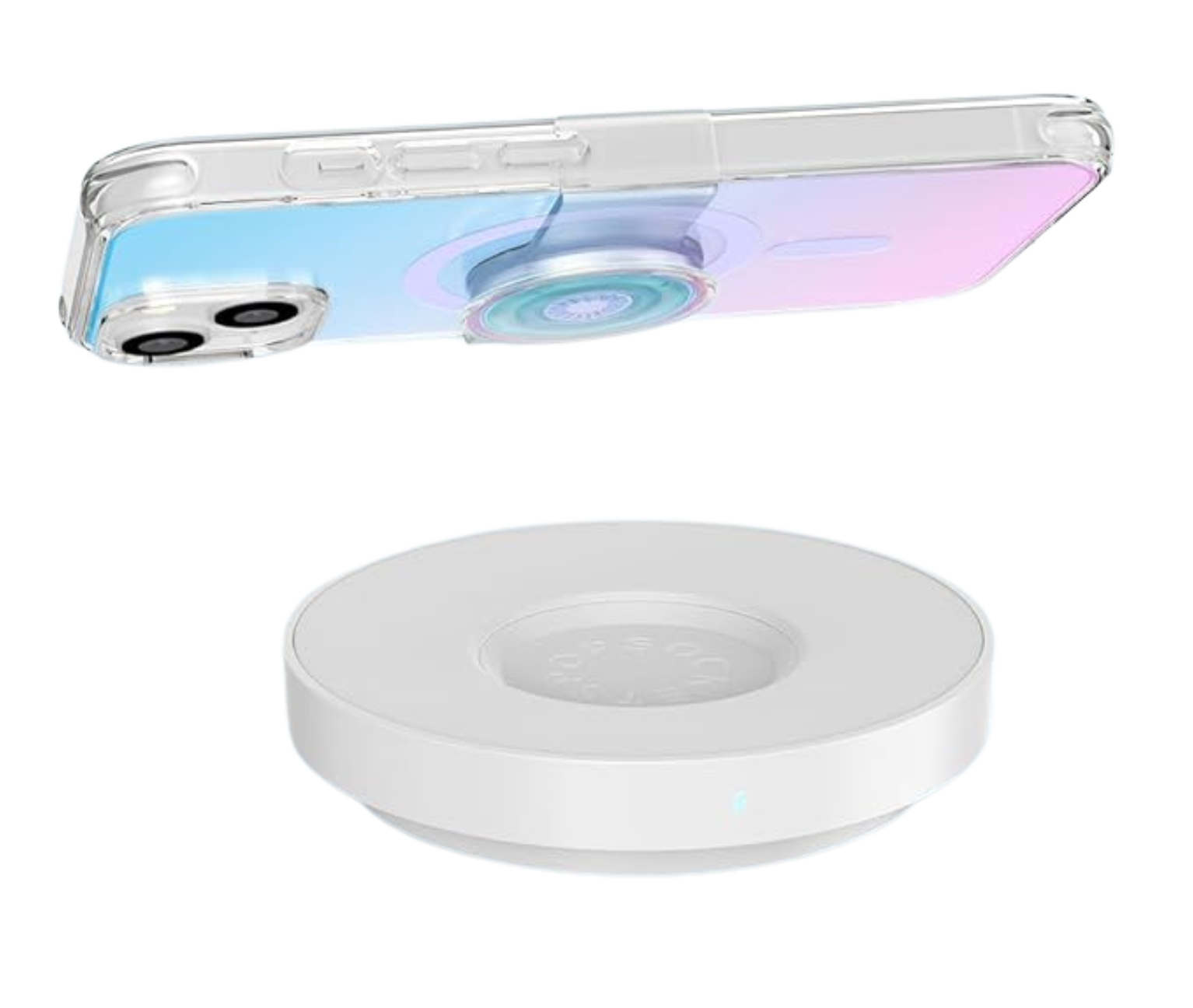

POPPOWER WIRELESS CHARGER

Company

PopSockets, Boulder, CO

Timeframe

2018-2019

Role

Senior Quality Engineer, Product Development

Project Goal

Develop a wireless charging pad capable of charging phones with a PopSockets grip, overcoming the increased stack height by extending the charging distance from 2-5 mm to 9-15 mm.